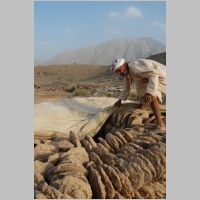

One of the 'pans' where the raw material soaks for three days |

The raw material has the consistency of talc |

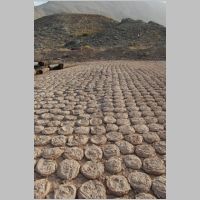

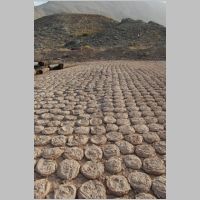

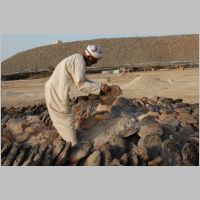

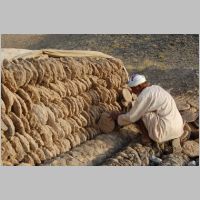

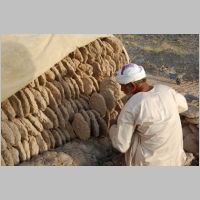

After curing for three days, the mud is shaped into discs |

Each disc is about the size of a large dinner plate |

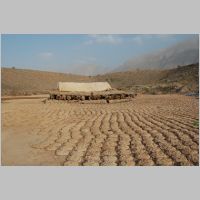

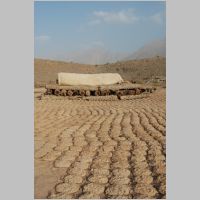

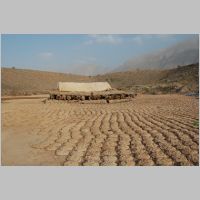

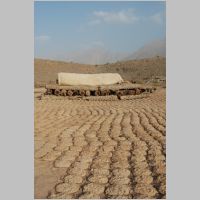

Thousands of the discs dry in the sun, waiting to be fired |

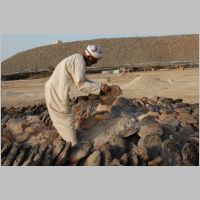

A hand to illustrate the relative size of each disc |

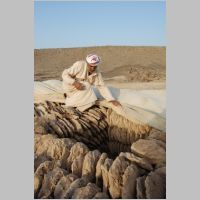

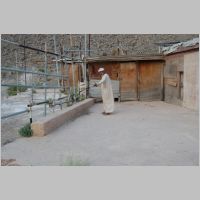

One of the workers near the field of discs |

Beyond the sun-drying discs is a recently fired pile of discs |

The fired discs, some ash-covered, some dark brown |

Many of the discs are still neatly stacked |

There were five sites for sarooj firing on the site |

A view down onto the stack of fired discs |

Three of the firing sites, the most recently fired in the foreground,

one pile fired days earlier, in the distance a stack being built |

The discs, once cool, are bulldozed into a pile |

Drying discs waiting to be stacked on the madbah in the distance |

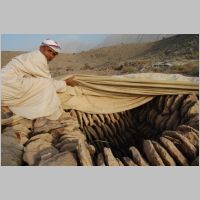

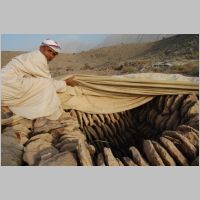

A tarp covers the stack of date palm trunks and mudbrick discs |

Several thousand mudbrick discs are fired at a time |

The manager estimated the quantity of discs at three tons |

The madbah is composed of three layers of date palms, eight meters by

eight meters |

One ton of wadi stones -- limestone? -- are placed between the date palm

trunks. |

A roller is used to crush the fired discs on steel plates |

Some of the 'modern' equipment used in sarooj manufacturing |

Some of the fired bricks waiting to be crushed |

Each layer of the madbah consists of 20 date palm trunks |

|

|

Fresh ash from the date palm trunks is visible on the perimeter |

|

One of the pans where mud is being used to make discs |

Each pan is quartered |

A complete pan, with another day or two before discs will be made |

|

A general view of the sarooj factory site |

The number of discs on the site was overwhelming |

Some of the date palm trunks to be used in firing |

|

The manager shows the premium discs after firing |

Like mudbricks found in copper smelters, the discs are very hard |

When banged together, the best discs have a metallic ring |

The manager demonstrating the test for quality firing |

|

|

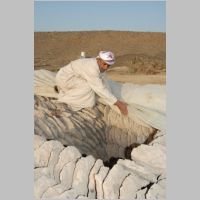

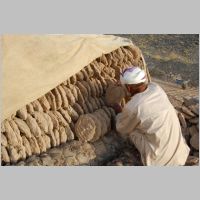

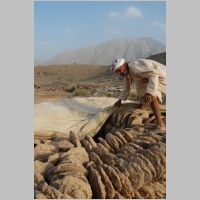

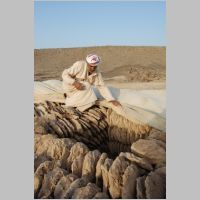

The stack of mudbricks on this madbah is about half complete |

A tarp protects the bricks in the event of rain or heavy dew |

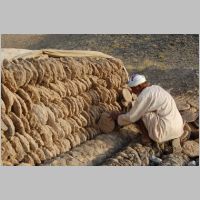

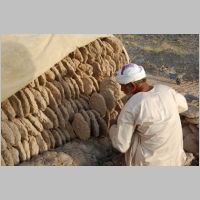

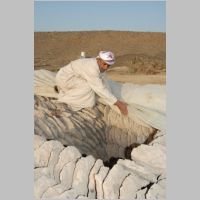

The manager demonstrating how the stack is organized |

Several 'chimneys' are constructed to improve air flow |

This 'chimney' extends down through the stack to the trunks |

|

|

The manager inside one of the 'chimneys' |

|

|

|

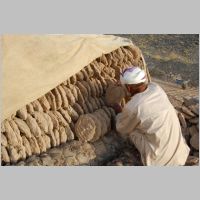

The manager demonstrates how the discs are stacked |

|

|

The stacking of the discs is very methodical |

|

|

|

|

|

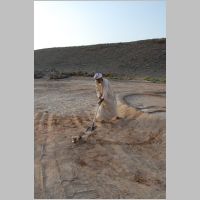

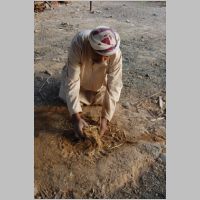

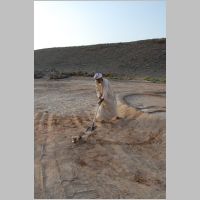

The manager demonstrates how each disc is shaped |

A shovel is used to collect a quantity of the mud |

|

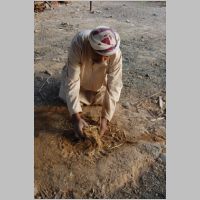

The worker shapes the disk |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Two finished discs |

|

The manager demonstrates how palm branches are placed between the date

palm trunks |

The palm branches ensure the fire spreads quickly through the stack |

|

|

|

|

|

|

|

|

The manager demonstrates how the finished product was used |

Water and straw was added |

|

|

Sarooj was tested here more than 25 years ago |

|

|

|

|

|

|

|

|

|

|

|

Once the well is formed, water is added and the final product made |

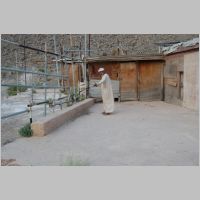

The manager showing some sarooj-built features |

|

|

This platform and low wall were made more than 25 years ago |

|

|

The manager demonstrates that the sarooj still is very hard |

The sarooj has many of the characteristics of cement |

|

|

|

|

|

|