Bulletin 6 - December 1978: Flint and the Prehistory of Abu Dhabi

Flint and the Prehistory of Abu Dhabi

by Rob WesternIntroduction

To most people nowadays the word "flint" is synonymous with cigarette lighters, but, in fact, these have nothing at all to do with the mineral flint. The word "flint" has almost passed out of the consciousness of modern man, being retained only in a few expressions such as "skin flint", "as hard as flint", and "you might as well wring water from a flint", each of which gives an indication of certain characteristics of the mineral.

The pieces of flint, which are commonly scattered throughout vast areas of the world, are no longer looked upon as possessing much significance. Yet, for literally hundreds of thousands of years, flint was one of the primary factors in man's developing existence. Today it is still used and worked by traditional methods by a few tribes in Australia and India and by the manufacturers of gunflints as at Brandon in Suffolk.

Appearance and Properties of Flint

In its natural state, pure flint is jet black in color and usually surrounded by a white coat called "cortex". This cortex is not derived from the immediate environment but is an integral part of the stone and may even form the bulk of it. Cortex is formed by the removal of water from the surface and its replacement by silica. The vast majority of flint encountered, however, will not be in the position in which it was formed. Erosion processes will have removed most of its original immediate environment. Such flint, when broken, becomes patinated, or stained, through subsequent contact with other minerals, oxygen and water. In its native form it is usually found either as lumps, known as nodules, or as flattish sheets, between one and 15 centimeters thick, known as tabular flint.

The mineral substance of flint is silica, other related forms of which include quartz, opal and chalcedony. Of all these, flint is the purest form of silica, at 98%. The exact origin of flint is still in dispute. The theories of silica globules forming in the Chalk Seas of Cretaceous times and becoming variously compressed into flint or chert (usually defined as flint from limestone horizons other than chalk), do not completely stand up to the present day evidence of location and availability. However, marine fossils are certainly not rare in the middle of nodules.

Flint is a very hard mineral and, though inferior to diamond, can be utilized successfully for cutting glass.

When struck by a piece of iron, a flint may appear to emit sparks, but these, in fact, are minute fragments of the iron struck off by the sharp edge of the harder flint concentrating the blow and thus raising the detached particles to white heat.

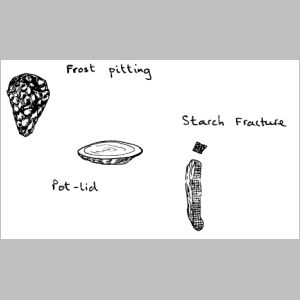

When shattered, flint breaks in a similar manner to glass, producing a splintery fracture. It can be broken by rapid temperature change, being a poor conductor of heat, and the results can be easily seen in desert areas, Abu Dhabi being no exception. Flint can also be split by frost if there is already a crack into which moisture can penetrate. The piece broken off is often a tiny disk with a convex inner surface. Sometimes a large nodule can be covered with such "pot-lids" and it is then said to be frost-pitted. A thick white cortex may also split, but into rods of remarkably square or rectangular section. This is known as "columnar" or "starch" fracture. It is important that neither of these types of natural fracture be confused with artificial fracture of flint by human agency.

Artificial Flaking

A flake that is purposefully struck from a parent flint with a degree of control tends to display certain characteristics. The exact area of striking contact, called the point of percussion, is often marked by a minute pimple at the edge where the flake broke away. Immediately below this dot on the detached flake there is usually a rounded protuberance known as the bulb of percussion. This is a result of conchoidal fracture, a corresponding negative bulb being found on the parent flint. Sometimes a smaller bulbar scar is evident on or just beneath the bulb of percussion. The rest of the flake sweeps away from the bulb, its surface rippled with shallow arc-like "waves", concentric about the point of percussion.

Often very fine fracture lines radiate from the point of percussion, crossing these "waves" at right angles. An ideal flake tapers to a thin sharp edge, but if the blow is weak, the result may be a hinge-fracture where the break at a certain point cuts back to the surface abruptly.

Since flint is the one artifact that has endured for millennia, a lot of research has gone into its properties of fracture. The methods of flaking employed by pre-historic man displayed a gradual advance in technology over an extremely long period. In some areas, other stones were used, such as quartz and obsidian, but flint was generally the first choice if available, for it can easily be chipped in any direction. The methods of flaking can be conveniently divided into percussion and pressure flaking.

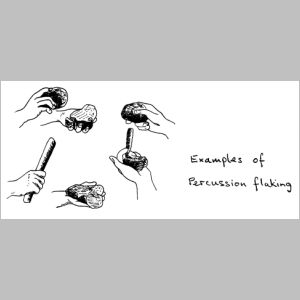

Flaking by PercussionThere are five main methods. The crudest was to hit one piece of flint against another, with poor control over the angle and point of impact. A second way was to rest the flint on another stone and then strike it with a third stone, called a "hammer stone". Because the force of the blow was reflected back from the bottom stone, there was sometimes a bulb of percussion at each end of the detached flake. A better way of shaping a nodule was to hold the work piece in one hand and strike it with a hammer stone held in the other. This method is still used by Australian aborigines. In the fourth method, the hammer stone was replaced by a baton of bone or hard wood, which was more useful for breaking off usable flakes. If the original nodule itself was shaped for use as a tool, the result is today known as a "core tool", to distinguish it from a "flake tool". The fifth method is known as indirect percussion. A small pointed stick was held between the fingers, its point resting upon a predetermined edge of the flint. The other end of the stick was then tapped with a hammer stone held in the other hand. A tiny flake was thereby struck from the underside of the parent flint.

Flaking by Pressure

Pressure flaking is a far more advanced technique than percussion flaking, and was generally used for finishing implements. Four main methods were used. In the first, the implement was held loosely in one hand and another piece of flint was used to scrape against the edge. This was further refined by holding the implement deep in the palm of one hand and using the other piece to press down upon its edges, detaching minute fragments. The palm absorbed any shock waves. A third method was to lay the nearly finished tool on a piece of thick hide or similar material and use a bone or sharp stick to ease tiny flakes off the edge. These three methods employ arm and shoulder pressure only. The fourth method was used by the Aztecs in historical times. Instead of a short bone or stick, a four or five foot stick was used. The craftsman placed one end on the piece of flint at the desired point and rested the other on a thick piece of protective hide against his chest. In this way he could bear down and exert far greater pressure.

Quite often it is possible to pick up a piece of flint and think it was worked by human agency. However, some of the results of artificial flaking can be emulated by nature. Such apparently worked flints are called "eoliths". A flint that has been rolled down a wadi in time of flood may exhibit apparent signs of percussion or pressure flaking, or both. A closer examination, however, should reveal the randomness of such fracturing, although the piece may end up shaped roughly like some sort of tool.

Evolution of Flint-knapping Techniques

Since the history of man's use of flint spans such a vast length of time, the chronology of technical change is both inexact and relative. Flint implements are thus better described in terms of function, rather than chronology, especially as developments took place at different times in different parts of the world. The Neolithic of North Africa, for example, is not to be chronologically equated with the British Neolithic.

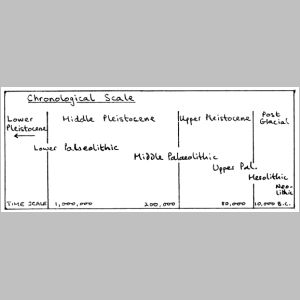

In very general terms, the time scale is divided into Lower, Middle and Upper Paleolithic (Old, Middle and New Stone Age), in prehistoric times. This covers at least the last two million years and belongs to the geological epoch knows as the Pleistocene, in which the major glaciations in the Northern Hemisphere occurred. The Lower Paleolithic itself covers more than 95% of this era, but it is the period about which least is known and understood.

A collection of flint artifacts in one location is known as an industry if it can be shown that there are similarities in technique and sequence. A collection of industries over a larger geographical area, preferably in association with other relevant evidence such as burial, adornments, pottery, is known as a culture. For obvious reasons, the Lower Paleolithic consists almost invariably of industries, not cultures. The names given to separate industries is usually derived from a type-site; for example, Acheulian is named after Saint Acheul on the Somme in France, and Aterian after Bir-el-Ater in Tunisia.

The Lower PaleolithicThe oldest implements so far discovered that were indisputably manufactured by hominids have been found in the lowest strata of the archaeological sequence in the Pliocene Lava tuffs of Olduvai Gorge in modern Tanzania. These have been potassium-argon dated to between 3.5 and 3.75 million years BP (before the present) and thus predate even the Pleistocene. Fossilized fragments of skeletal remains were found in association with the artifacts. The implements concerned were core tools, the majority being river pebbles roughly chipped at one end to form a cutting or hacking edge.

During the next three million years, the world wide record sheet remains very sparse. Towards the end of this period, similar pebble tools turn up in stratified sequences in Northern India (Soan industry) and Northern China in the caves of Choukoutien near Peking. In Africa, there was an extremely gradual development in technique from mere shaping of a stone at one end to flaking all over. Slowly there evolved the first standardized tool, the hand axe, an unshafted implement held in the hand and used for a multitude of tasks associated with a hunting economy. This implement, the major tool of the Acheulian industrial tradition, spread first throughout Africa and thence into Europe and Asia.

As time passed, it became smaller, more refined in shape, and thinner in section, culminating in some of the finest examples of Lower Paleolithic craftsmanship yet discovered. The Acheulian tradition in fact endures in some parts of the world into the Upper Paleolithic and at some point it seems clear that an aesthetic element must have crept in.

Most of these earliest tools were formed from cores but flakes, originally waste material, were utilized from time to time if they were large enough and could be put to some use. Among the earliest implements found in Britain are both core and flake Acheulian type aces from old banks of the Thames and dating to over 200,000 years BP.

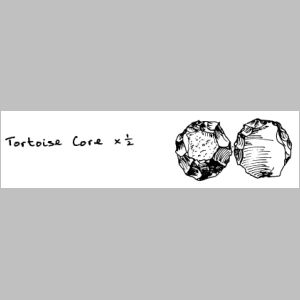

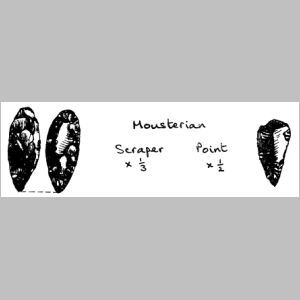

The Middle PaleolithicThe development of flake tools in their own right is a feature of the Middle Paleolithic (approx. 100,000 to 35,000 BP). The chief technical advance that marks the beginning of this period is the use of prepared cores. Instead of random flakes being utilized, the parent flint itself was so chipped as to predetermine the exact size and shape of a particular flake, or series of flakes. Such flakes could be put to immediate use or could be further trimmed, or retouched. One side was completely smooth and the characteristic tools were convex sided scrapers and triangular points.

This industry is generally known as Mousterian (La Moustier, in the Dordogne, France), and is associated with Neanderthal man whose culture for the first time shows features that are typically human, such as the practice of burial. This period also gives the first clear indication of regular dwellings, and the advance of populations into more northern, harsher climates, suggesting definite progress in cultural technology.

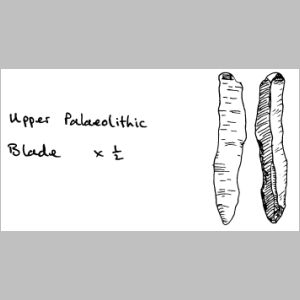

The Upper PaleolithicThis period (approx. 35,000 to 10,000 BP) spans the end of the final glaciation in the Northern hemisphere. Neanderthal man disappears rather abruptly at around 35,000 MP and there is evidence of successive population movements, particularly into Europe from the East. Technologically, the period is marked by increasing regional specialization, and by the rise in importance of blade tools. Cores were even more precisely shaped to produce more-or-less parallel sided blades. For the first time, the bow and arrow and harpoon entered mankind's hunting armory. Pressure flaking produced some of the most beautiful implements, such as finely tanged and barbed arrowheads. This period is also noted for the production of burins, small tools with the specific function of gouging and carving; in fact, the first recognizable stone awls and needles. There is a further population advance to previously unoccupied areas.

The Mesolithic

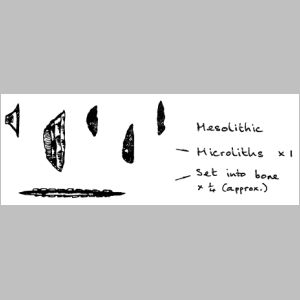

With the final retreat of the last ice age, there is a definite break with the past and it is at this point, around 10,000 BP, that regionalism takes over. Relatively small geographical areas, such as South Yorkshire, Northwest Spain, part of Denmark, show the influence of different groups experimenting and diversifying their economy. However, the archaeological record is by no means clear and conflicting interpretations are commonplace. Traditionally, the period is known as the Mesolithic in Northwest Europe and fills that gap between the end of the last glaciation and the beginning of agricultural and stock-rearing communities. The era of the Great Plains animals - bison, mammoth, giant elk - had gone, and Mesolithic groups had to adapt to an environment of increasing afforestation, which meant smaller game. Some tribes collected shell-fish and their waste-mounds (middens) can be found in great numbers around the Scottish coast. The principal implements are still of flint, the emphasis now being on tiny shaped flakes known as microliths, which were set in rows on wood or bone handles and used as cutting and sawing tools. The sowing and reaping of barley began in Mesolithic times in the Middle East and flint sickles showing "silica-gloss" have been found in Palestine dating to about 6000BC.

The Neolithic

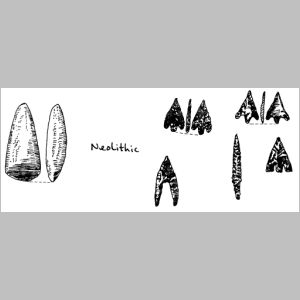

The finest and most delicate flint-work is to be found in Neolithic times, that period succeeding Mesolithic cultures and which also witnessed the rise in farming and urban civilization. Blades and arrow-heads were flaked so finely as to be translucent, and some of the shapes, such as foliates and laurel-leaf points, were exquisitely manufactured. Perhaps the finest worked piece of flint ever discovered is a knife some 30 cm long and 5 cm wide found in an Egyptian tomb of c. 3000 BC. The entire surface was polished, and then lightly ripple-flaked all over. Polishing of flint and stone implements is a feature of the Neolithic and there is evidence for extensive trade in good quality flint and like stones.

The rise of the metal-using cultures of the Eastern Mediterranean in the 5th millennium BC profoundly altered man's approach to the manufacture of implements. For a while flint continued to predominate outside the privileged metal-using areas. Some arrowheads and smaller blades display definite signs of having been copied from metal originals. As man's development approaches historical times, it could be said that the writing was on the wall for flint, except in areas untouched by the Middle-eastern impetus. However, wherever there is flint today, the testimony of the past is never far away, and the future can only help to slot more pieces into the prehistoric jigsaw.